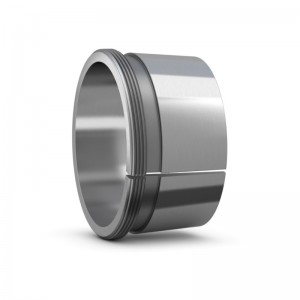

Lock nut KM05 KM06 KM07

Locking nut locking principle:

The working principle of the nut is self-locking using the friction between the nut and the bolt. However, the reliability of this self-locking will be reduced under dynamic loads. In some important occasions, we will take some anti-loosening measures to ensure the reliability of the nut lock. The use of locking nuts is one of the anti-loosening measures. The lock nut generally relies on friction, and its principle is to press into the preset hole of the sheet metal through the embossed teeth, and the aperture of the general square preset hole is slightly smaller than that of the riveted nut. The nut is connected with the locking mechanism. When the nut is tightened, the locking mechanism locks the ruler body, and the ruler frame cannot move freely to achieve the purpose of locking; When the nut is loosened, the locking mechanism is removed from the ruler body and the ruler frame moves along the ruler body.

There are several types of lock nuts:

High strength self-locking nuts: A classification of self-locking nuts, with high strength and high reliability.

Nylon self-locking nut: Nylon self-locking nut is a new type of high vibration and anti-elastic fastening parts.

Movable self-locking nut: The movable self-locking nut of double-ear seal is composed of four parts: sealing cover, self-locking nut, pressure ring and sealing ring.

Spring self-locking nut: spring clamp self-locking nut, which is composed of S-type spring clamp and self-locking nut.

|

Designations |

screw thread |

Boundary Dimensions |

Lock washer |

Lock plate |

W.t |

|||||

|

d |

d1 |

d2 |

B |

b |

h |

KG |

||||

| KM 05 |

M 25×1.5 |

25 |

32 |

38 |

7 |

5 |

2 |

MB 05 |

– |

0.028 |

| KM 06 |

M 30×1.5 |

30 |

38 |

45 |

7 |

5 |

2 |

MB 06 |

– |

0.038 |

| KM 07 |

M 35×15 |

35 |

44 |

52 |

8 |

5 |

2 |

MB 07 |

– |

0.058 |

| KM 08 |

M 40×1.5 |

40 |

50 |

58 |

9 |

6 |

2.5 |

MB 08 |

– |

0.078 |

| KM 09 |

M 45×1.5 |

45 |

56 |

65 |

10 |

6 |

2.5 |

MB 09 |

– |

0.11 |

| KM 10 |

M 50×1.5 |

50 |

61 |

70 |

11 |

6 |

2.5 |

MB 10 |

– |

0.14 |

| KM 11 |

M 55×2 |

55 |

67 |

75 |

11 |

7 |

3 |

MB 11 |

– |

0.15 |

| KM 12 |

M60×2 |

60 |

73 |

80 |

11 |

7 |

3 |

MB 12 |

– |

0.16 |

| KM 13 |

M65×2 |

65 |

79 |

85 |

12 |

7 |

3 |

MB 13 |

– |

0.19 |

| KM 14 |

M70×2 |

70 |

85 |

92 |

12 |

8 |

3.5 |

MB 14 |

– |

0.22 |

| KM 15 |

M75×2 |

75 |

90 |

98 |

13 |

8 |

3.5 |

MB 15 |

– |

0.27 |

| KM 16 |

M60×2 |

80 |

95 |

105 |

15 |

8 |

3.5 |

NB 16 |

– |

0.36 |

| KM 17 |

M85×2 |

85 |

102 | 110 |

16 |

8 |

3.5 |

MB 17 |

– |

0.42 |

| KM 18 |

M90×2 |

90 |

108 | 120 |

16 |

10 |

4 |

MB 18 |

– |

0.51 |

| KM 19 |

M95×2 |

95 |

113 | 125 |

17 |

10 |

4 |

MB 19 |

– |

58 |

| KM 20 |

M100×2 |

100 |

120 | 130 |

18 |

10 |

4 |

MB 20 |

– |

0.68 |

| KM 21 |

M 105×2 |

105 |

126 | 140 |

18 |

12 |

5 |

MB 21 |

– |

0.81 |

| KM 22 |

M110×2 |

110 |

133 | 145 |

19 |

12 |

5 |

MB 22 |

– |

0.89 |

|

KM 23 |

M115×2 |

115 |

137 |

150 |

19 |

12 |

5 |

MB 23 |

– |

0.91 |

|

KM 24 |

M120×2 |

120 |

138 |

155 |

20 |

12 |

5 |

MB 24 |

– |

0.98 |

|

KM 25 |

M 125×2 |

125 |

148 |

160 |

21 |

12 |

5 |

MB 25 |

– |

1.10 |

|

KM 26 |

M130×2 |

130 |

149 |

165 |

21 |

12 |

5 |

MB 26 |

– |

1.20 |

|

KM 27 |

M 135×2 |

135 |

160 |

175 |

22 |

14 |

6 |

MB 27 |

– |

1.40 |

|

KM 28 |

M 140×2 |

140 |

160 |

180 |

22 |

14 |

6 |

MB 28 |

– |

1.40 |

|

KM 29 |

M 145×2 |

145 |

171 |

190 |

24 |

14 |

6 |

MB 29 |

– |

1.85 |

|

KM30 |

M150×2 |

150 |

171 |

195 |

24 |

14 |

6 |

MB 30 |

– |

1.85 |

|

KM31 |

M 155×3 |

155 |

182 |

200 |

25 |

16 |

7 |

MB 31 |

– |

2.05 |

|

KM 32 |

M160×3 |

160 |

182 |

210 |

25 |

16 |

7 |

MB 32 |

– |

2.25 |

|

KM 33 |

M 165×3 |

165 |

193 |

210 |

26 |

16 |

7 |

MB 33 |

– |

2.30 |

|

KM 34 |

M170×3 |

170 |

193 |

22 |

26 |

16 |

7 |

MB 34 |

– |

2.55 |

|

KM 36 |

M 180×3 |

180 |

203 |

230 |

27 |

18 |

8 |

MB 36 |

– |

2.70 |

|

KM 38 |

M190×3 |

190 |

214 |

240 |

28 |

18 |

8 |

MB 38 |

– |

3.00 |

|

KM 40 |

M 200×3 |

200 |

226 |

250 |

29 |

18 |

8 |

MB 40 |

– |

3.30 |

For more information , please contact our email :info@cf-bearing.com