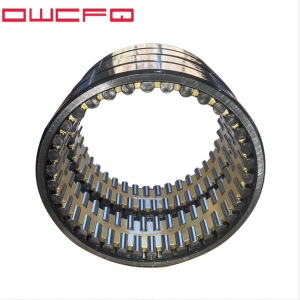

Single row cylindrical roller bearing 32052/HCDF for vertical mill

The single row cylindrical roller bearings we provide for vertical mills are high-performance bearings designed specifically for vertical coal mills, vertical cement mills, and other heavy-duty grinding equipment. This bearing adopts high-quality materials and precision machining technology, which can effectively withstand high radial loads, provide excellent durability and operational stability, and is widely used in vertical grinding equipment in industries such as cement, steel, power, and mining.

Product features and advantages

High load-bearing capacity:

Single row cylindrical roller bearings adopt a linear contact structure, which can effectively withstand large radial loads. Compared with other types of bearings, cylindrical roller bearings have higher load-bearing capacity and are suitable for high load and high impact working environments, ensuring stable operation of vertical mills under heavy load conditions.

Excellent durability:

The bearing is made of wear-resistant materials and has undergone precision heat treatment and surface treatment, possessing excellent fatigue resistance. Even under high load and high-speed operating conditions, the service life of bearings can be effectively extended, reducing maintenance frequency and downtime.

Low friction coefficient:

Due to the small contact area between the rolling elements and the raceway of cylindrical roller bearings, the friction coefficient is low, which helps to improve mechanical efficiency, reduce energy consumption, and effectively suppress heating phenomena, thereby improving the working efficiency and service life of vertical mills.

High precision manufacturing:

The bearings are precision machined to ensure high geometric accuracy and operational stability of the inner and outer rings as well as the rolling elements. Precise design and processing can not only improve the working performance of bearings, but also reduce noise and vibration during operation, ensuring the smooth operation of equipment.

Strong pollution resistance:

The working environment of vertical mills is usually harsh and susceptible to pollutants such as dust and moisture. Our single row cylindrical roller bearing design has strong anti pollution ability, which can effectively prevent external pollutants from entering the interior of the bearing and ensure long-term stable operation.

Optimized structural design:

The bearing has a compact structure, good rigidity, and is suitable for withstanding large radial loads and certain axial loads. Suitable for key parts that transmit power in vertical mills, such as grinding disc shafts and reducers.

Flexible application scope:

Suitable for various heavy load and high impact industrial equipment, especially in vertical mills in industries such as cement, steel, and mining, it can effectively improve the operating efficiency of equipment and extend its service life.

application area

Cement industry: Vertical mills are widely used in the grinding system of cement production lines. Single row cylindrical roller bearings can effectively support the rotation of grinding rollers and grinding discs, and withstand high loads and impact loads.

Steel industry: In the vertical mills of the steel industry, this bearing can work stably, help efficiently grind ores and coal powder, and improve production efficiency.

Mining industry: Suitable for various vertical grinding machines in mining machinery, helping equipment withstand heavy loads and ensuring long-term stable operation.

Power industry: In coal grinding equipment in power plants, the high load capacity and pollution resistance of bearings help improve the reliability and service life of the equipment.

Product specifications

Model: Single row cylindrical roller bearing 32052/HCDF

Size range: d: 260mm D: 400mm B: 174mm

Tolerance grade: High precision manufacturing, meeting ISO standard requirements.

Why choose our single row cylindrical roller bearings?

Excellent load capacity and stability: Its high load-bearing capacity and strong wear resistance make it perform outstandingly in high load working environments.

Long life and low maintenance: High quality manufacturing processes and fatigue resistant design greatly extend the service life of bearings and reduce maintenance frequency.

Efficient and energy-saving: The low friction coefficient improves the working efficiency of the vertical mill, effectively reducing energy consumption.

Anti pollution design: Excellent anti pollution ability ensures long-term stable operation of bearings and adapts to harsh working conditions.

Wide applicability: Suitable for various industries such as cement, steel, mining, and electricity, and flexibly applied to different types of vertical mills.

conclusion

Our vertical grinder uses single row cylindrical roller bearings with high-precision design and high load-bearing capacity, which are particularly suitable for vertical grinder equipment in industries such as cement, steel, and mining. Whether under high loads, impact loads, or harsh working environments, this bearing can provide excellent performance and a long service life, helping you reduce downtime, lower maintenance costs, and improve production efficiency.