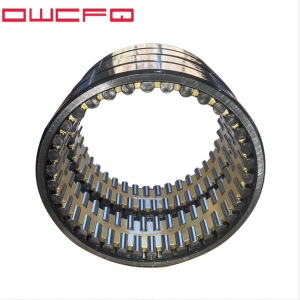

Spherical Roller Bearings CC

Features

Spherical roller bearings have two rows of spherical rollers, the outer ring has a common concave spherical raceway, the inner ring has two concave raceways inclined at an angle to the bearing axis, and the center of curvature of the outer ring raceway is Bearing center is the same. The spherical roller bearing is self-aligning and is not affected by the misalignment of the shaft and the bearing housing or the deformation and deflection of the shaft, and can compensate for the concentricity error caused thereby. In addition to bearing radial load, this type of bearing can also bear bidirectional axial load and its combined load, with large bearing capacity and good anti-vibration and impact resistance.

Spherical roller bearings have 2, standard (N), 3, 4 and 5 sets of internal clearances, while tapered bore spherical roller bearings use 3 sets of clearances as the standard clearance. Bearings larger or smaller than the standard value of clearance can also be produced according to user requirements.

Vibration machinery bearings need to use larger radial clearance, 3, 4 groups or non-standard clearance between 3 and 4.

The spherical roller bearing for vibrating screen has 4 sets of clearance.

Easy to install:

Spherical roller bearings have two types of inner holes: cylindrical and conical. The taper of the conical taper hole is 1:12 and 1:30. This conical inner hole bearing is equipped with an adapter sleeve or a withdrawal sleeve. The tapered inner bore spherical roller bearing can be easily and quickly assembled on the optical shaft or stepped machine shaft.

product Range :

Inner diameter size range: 45mm~440mm

Outer diameter size range: 90mm~600mm

Width size range: 23mm~243mm

CA spherical roller bearings, inner ring without center ribs, small ribs on both sides, fitted with symmetrical rollers, solid brass cage

CAC self-aligning roller bearings, inner ring without center ribs, small ribs on both sides, with movable center rings, symmetrical rollers, solid brass cage

CC self-aligning roller bearing, inner ring without ribs, with movable middle retaining ring, equipped with symmetrical rollers, stamped cage

MA type self-aligning roller bearing, the inner ring roller guide method has been improved (roller surface roughness, raceway surface roughness, heat treatment method change, etc.) to reduce friction (special bearing for vibrating screen)

MB spherical roller bearings, inner ring with central ribs, small ribs on both sides, fitted with symmetrical rollers, solid brass cage

/C3 The clearance conforms to the 3 groups stipulated in the standard

/C4 Clearance conforms to the 4 groups stipulated in the standard

/C9 bearing clearance is different from the current standard

/CRA9 bearing radial clearance is non-standard, axial clearance is required

D split bearing

F1 carbon steel

F3 Ductile Iron

/P5 tolerance class conforms to the 5th class stipulated in the standard

/P6 tolerance class conforms to the 6th class stipulated in the standard

/HA ring rolling elements and cages or only rings and rolling elements are made of vacuum smelted bearing steel

/HC rings and rolling elements or only rings or only rolling elements are made of carburized steel (/HC-20Cr2Ni4A;

/HC1 20Cr2Mn2MoA;/HC2-15Mn;/HC3-G20CrMo)

/HCR means that in the same specification, only the rolling elements are made of carburized steel

/HG rings and rolling elements or only rings are made of other bearing steels (/HG-5GrMnMo;/HG1-55SiMoVA;/HG2-GCr18Mo;/HG3-42CrMo;/HG4

GCr15SiMn) manufacture

K tapered bore bearing, taper 1:12

K30 tapered bore bearing, taper 1:30

N Stop groove on bearing outer ring

NR bearing outer ring snap groove with snap ring

Q1 Al-Fe-Mn Bronze

-2RS Bearings with RS seals on both sides

-2RS2 bearings with steel skeleton fluorinated rubber seals on both sides

The /S0 bearing ring has been tempered at high temperature, and the working temperature can reach 150°C

The /S1 bearing ring has been tempered at high temperature, and the working temperature can reach 200°C

The /S2 bearing ring has been tempered at high temperature, and the working temperature can reach 250°C

The /S3 bearing ring has been tempered at high temperature, and the working temperature can reach 300°C

/S4 Bearing rings are tempered at high temperature, and the working temperature can reach 350°C

/W20 There are three lubricating oil holes on the outer ring of the bearing (no oil groove)

There are oil grooves and three lubricating oil holes on the outer ring of the /W33 bearing

/W33T There are eight lubrication holes on the outer ring of the bearing

There are oil grooves and six lubricating oil holes on the outer ring of the /W33X bearing

X1 outer diameter non-standard

X2 width (height) non-standard

X3 outer diameter, width (height) non-standard (standard inner diameter)