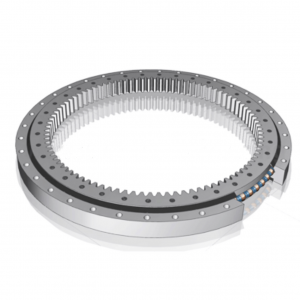

Thin slewing ring bearing internal gear 062 series

| Model | Wght | Dimensions(mm) | Mounting Dimensions(mm) | Gear data | Clearance Axial | Clearance Radial | |||||||||||||

| kg | D | de | H | DI | D2 | na | φ | M | t | d | m | z | k.m | b | Load allow KN | Load max KN | |||

| 062.20.0414 | 31 | 486 | 326.5 | 56 | 460 | 375 | 24 | 13.5 | 12 | 20 | 335 | 5 | 67 | -0.8 | 45.5 | 13.54 | 27.08 | ≤0.28 | ≤0.24 |

| 062.20.0544 | 42 | 616 | 445.2 | 56 | 590 | 505 | 32 | 13.5 | 12 | 20 | 456 | 6 | 76 | -0.6 | 45.5 | 16 | 32.00 | ≤0.30 | ≤0.26 |

| 062.20.0644 | 50 | 716 | 547.2 | 56 | 690 | 605 | 36 | 13,5 | 12 | 20 | 558 | 6 | 93 | -0.6 | 45.5 | 15.62 | 31.24 | ≤0.30 | ≤0.26 |

| 062.20.0744 | 58 | 816 | 649.2 | 56 | 790 | 705 | 40 | 13.5 | 12 | 20 | 660 | 6 | 110 | -0.6 | 45.5 | 15.32 | 30.64 | ≤0.30 | ≤0.26 |

| 062.20.0844 | 69 | 916 | 737.6 | 56 | 890 | 805 | 40 | 13.5 | 12 | 20 | 752 | 8 | 94 | -0.8 | 45.5 | 20.80 | 41.60 | ≤0.30 | ≤0.26 |

| 062.20.0944 | 76 | 1016 | 841.6 | 56 | 990 | 905 | 44 | 13.5 | 12 | 20 | 856 | 8 | 107 | -0.8 | 45.5 | 20.49 | 40.98 | ≤0.30 | ≤0.26 |

| 062.20.1094 | 91 | 1166 | 985.6 | 56 | 1140 | 1055 | 48 | 13.5 | 12 | 20 | 1000 | 8 | 125 | -0.8 | 45.5 | 20.16 | 40.32 | ≤0.30 | ≤0.26 |

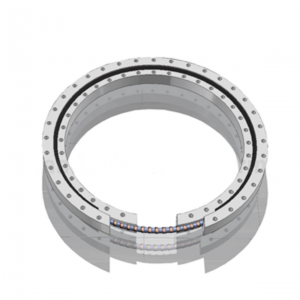

Light Type Slewing Bearing – The Solution for Your Renewable Energy Applications

If you are looking for a reliable and efficient solution for your renewable energy applications, then our Light Type Slewing Bearing is the perfect choice for you. With its high load capacity and smooth rotation, this product is ideal for a wide range of renewable energy applications, including wind turbines and solar trackers.

Our Light Type Slewing Bearing is made from high-quality materials and is designed to withstand the toughest conditions. It is also easy to install and requires minimal maintenance, making it a cost-effective solution for your business.

So why wait? Contact us today to learn more about our Light Type Slewing Bearing and how it can help you improve your renewable energy applications and increase your profitability.

Installation and Maintenance of Light-duty Slewing Bearings

Proper installation and maintenance are essential for ensuring the long-term performance and durability of light-duty slewing bearings. During installation, the bearing must be properly aligned and secured to prevent misalignment and premature wear. Regular maintenance, such as lubrication and inspection, is also necessary to ensure the bearing is operating at peak performance. Any signs of wear or damage should be addressed immediately to prevent further damage and potential failure.

Future Developments in Light-duty Slewing Bearings

As technology continues to advance, so do the capabilities of light-duty slewing bearings. Future developments may include the use of advanced materials, such as composites and ceramics, to further reduce weight and increase durability. New manufacturing techniques, such as 3D printing, may also be used to create more complex and customized designs. Additionally, advancements in sensor technology may allow for real-time monitoring of bearing performance, enabling predictive maintenance and reducing downtime.